Multi-scale modelling and analysis of dynamic CO2 capture, injection and storage

Clea Kolster

Supervisors: Dr Samuel Krevor and Dr Niall Mac Dowell

Funding: NERC Doctoral Training Program with the Grantham Institute’s Science and Solutions for a Changing Planet (SSCP)

As Carbon Capture and Storage (CCS) is making its way forward to deployment around the world, one of the principal remaining barriers are the costs involved and a lack of economic incentive for investment. CCS is a crucial technology for slowing down climate change and reducing greenhouse gas emissions for two major reasons:

- It is currently the only available option for decarbonising the heavy industry sector

- It is necessary to complement intermittent renewable energy sources with low carbon-intensity fossil fuel powered energy sources

The overall aim of this project is to obtain a full chain, integrated model of the carbon capture, transport and storage process that incorporates the effects on transport and storage that may stem from having a dynamic and intermittent production of carbon dioxide. With regards to the storage process, the focus of this work will be on storage in saline aquifers, depleted oil and gas reservoirs and capture product usage for CO2 Enhanced Oil Recovery (EOR). CO2-EOR in the North Sea provides a very important economic incentive for CCS in Europe and can help accelerate its deployment. The full chain model will also allow for identifying cost reduction potential at different points in the process and establish how certain variations would affect the rest of the chain.

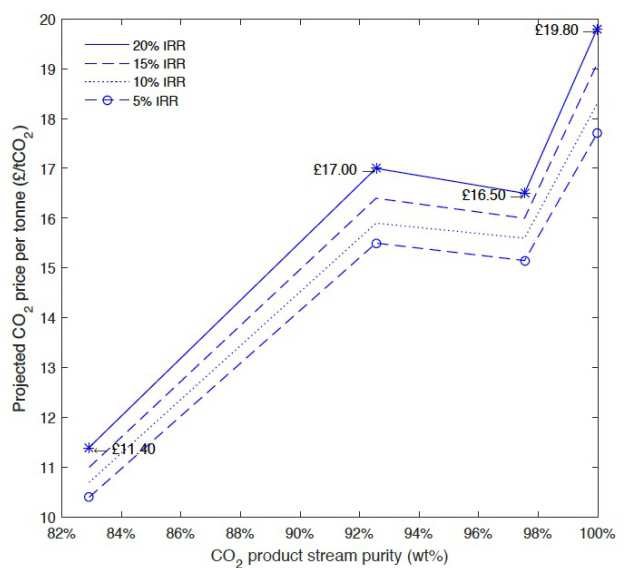

So far, the project has focused on the techno-economic analysis of gas purification and compression for CO2 capture, benefits of shared CO2 capture infrastructure and transport networks. In this work, we have identified that within the oxy-combustion capture process (one of the most mature technologies for CO2 capture) there exists a trade-off between system cost and product purity. This trade-off stems from the CO2 compression and purification unit (CO2CPU) which takes in raw flue gas produced as a result of burning fuel in a high-oxy environment as opposed to burning the fuel in air. In this work, we have modeled four variations of the CO2CPU in Aspen HYSYS with each system varying in their method of separation. The four models in order of descending complexity are: a CO2CPU with a 6-stage distillation column, one with a double flash system with heat integration, a double flash system without heat integration and the least complex with only compression and dehydration. The results from these models show that an increase in product purity and complexity results in a reduction in capture efficiency. The capital and operational cost results for each CO2CPU modeled were translated into a price for the CO2 product stream. This is represented in Figure 1. In order to derive a price for each product, it was assumed that the CO2CPU is an independent entity in which to invest, with two inlet streams - raw flue gas (free) and energy (cost) - and two outlet streams - CO2 product (revenue) and waste stream. Figure 1 shows that at four different minimum rates of return (equated to the internal rate of return IRR), we find a non-linear and non-monotonic relationship between CO2 price and purity.

Figure 1: Graph showing the CO2 price per tonne sold if marketed assuming a minimum rate of return on investment of 20%, 15%, 10% and 5% on the CO2CPU as a function of CO2 stream purity

The difference between the highest purity product at 99.98wt.% CO2 and the lowest purity product at 82.91wt.% CO2 represents a 42% reduction in price.

As part of this work we have also assessed the difference in cost that would stem from having one large CO2 Compression and Dehydration unit with an intake of 20 Mt CO2/year as opposed to four smaller CO2 Compression and Dehydration units each with an intake of 5 Mt CO2/year. As a result we found that having one larger plant as opposed to four small ones would reduce total capital expenditure by 16% and yearly operational costs by 4%.

In addition, we evaluated the cost reduction that results from having several sources of CO2 at different purities entering a hypothetical transport network and leading to one final CO2 trunk line that is suitable for storage. Significant cost reductions were shown to stem from having high purity streams (e.g. CO2 stream from amine-based post combustion capture applied to a gas CCGT plant) mixed with lower purity, low cost CO2 streams (e.g. CO2 from an oxy-combustion coal firing power plant with a low cost, low complexity CO2CPU), whilst obtaining a final CO2 product of suitable purity for injection.

The next part of this project will focus on modeling the dynamic injection of CO2 into the Bunter Sandstone saline aquifer in the Southern North Sea, assessing the efficiency of storage and the proportion of CO2 that has undergone residual or dissolution trapping. This will be achieved using a combination of reservoir modelling tools (ECLIPSE and Petrel) and process modelling tools (gPROMS).