Biorenewable value chain optimization with multi-layered value chains and advanced analytics

Anna Panteli

Supervisors: Prof Nilay Shah and Dr Sara Giarola

Funding: Renewable Systems Engineering (RENESENG) – FP7 Marie Curie project

The PhD project entitled, “Biorenewable value chain optimization with multi-layered value chains and advanced analytics”, stems from the RENESENG (Renewable Systems Engineering) which is a FP7 Marie Curie project with the ultimate goal to delivering a sophisticated tool for biorefinery planning and design, integrating process simulation and optimisation across multi-scale. Precisely, this PhD project fits into the general project framework, as it focuses on the development of optimisation tools to support strategies for the screening and evaluation of biomass-to-biobased chemical production routes. A mixed-integer linear programming (MILP) model is being formulated in order to identify the promising routes to selected products, obtained from lignocellulosic biomass, as well as the corresponding optimal feedstock mix. This methodology will enable a systematic design of biorefining systems as well as the evaluation of key performance indicators (e.g. costs, environmental impacts). Case studies will be proposed to show the model capabilities in driving decision-making in the biorefinery design.

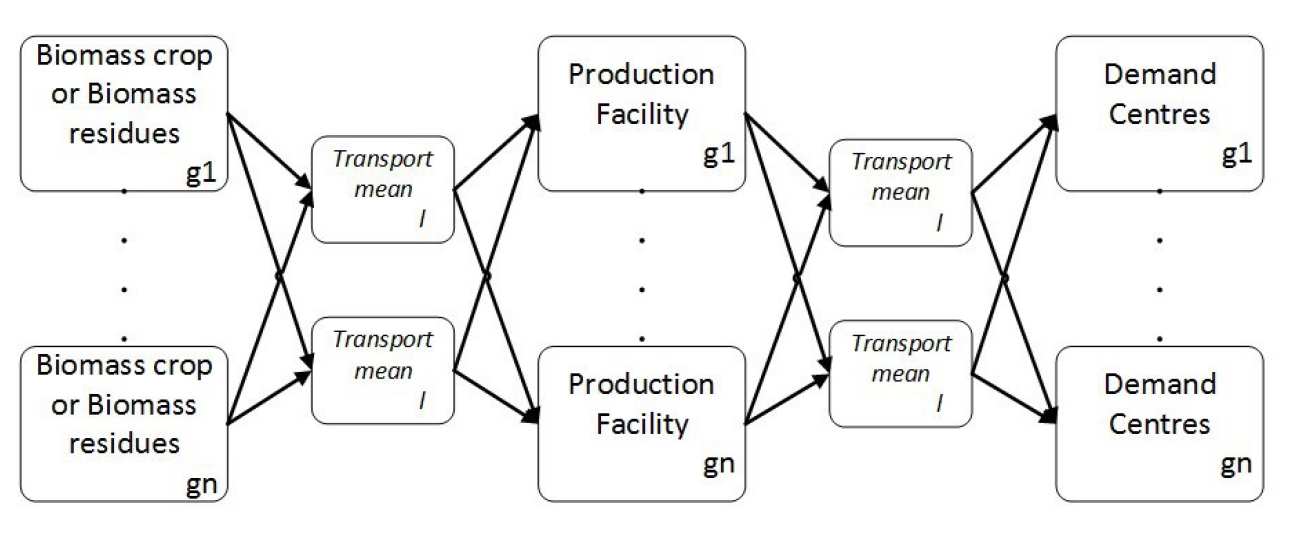

During the first year of the PhD, a literature review has been followed by supply chain integration with a superstructure model. This work was presented as a poster in the ESCAPE25/PSE2015 conference. Moreover, this preliminary modeling framework has been applied to an Organosolv-based biorefinery in the South-West of Hungary. This European case study was presented in the 2015 International Energy Workshop (IEW). In particular, this supply chain optimisation problem is formulated as a MILP model, solved in GAMS. The model represents a multi-period, multi-feedstock and multi-echelon supply chain model, aiming at determining the configuration of the biomass network to supply a biorefinery with the necessary biomass, maximizing the overall profit of the system, fulfilling targeted regional bioproduct demand over the entire planning horizon. The formulation of the model includes spatially-explicit features in order to capture the geographical availability of biomass crops and transportation links. The model enables the identification of the optimal size and location of biorefineries, storage and cultivation sites in a specific geographical context, the optimal feedstock mix supplied to the selected facilities as well as the optimal logistics.

The model, embedding the definition of the process technology superstructure for a portfolio of selected biobased products (e.g. ethanol) and platform chemicals (e.g. itaconic acid), will enable the analysis of the key sources of uncertainty in the planning of biorefining systems (e.g. capital and operating costs, technological yields) and their evolution over time. This is considered to be one of the main future research steps and combined with the work so far, was submitted in the AIChe 2015 conference.