The petrochemical industry faces a significant challenge in measuring corrosion damage in pipes. Such damage is most likely to occur in hard-to-inspect locations, such as where pipes meet their support structures, or where they are buried beneath the earth. For cost-effective and accurate risk management, it is essential that operators can determine the remaining wall thickness of pipes in-situ. Guided-waves are a valuable tool for this.

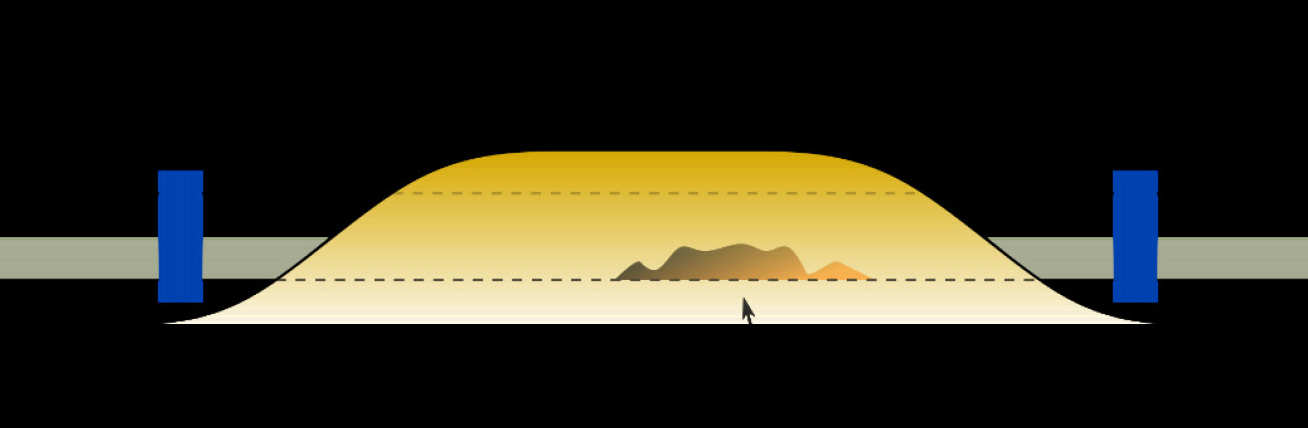

Guided waves are transmitted along the pipe using arrays of transducers placed in rings on either side of the region being inspected. The waves scatter when they encounter deviations in the wall thickness, and a thickness map can be formed from the reflected and transmitted signals. There are many ways of transforming these measurements into a thickness map, one of which is full-waveform inversion.

Full-waveform inversion uses highly-detailed simulations of the measurement process to form the thickness map. The process begins with a defect-free geometry (e.g. a uniform pipe), and iteratively updates the wall-thickness in a spatially varying manner until the simulated and real-life measurements agree. Pogo---the NDE group’s in-house wave simulation software---is critical to the feasibility of this approach, as it enables rapid iterations during the inversion process.