|

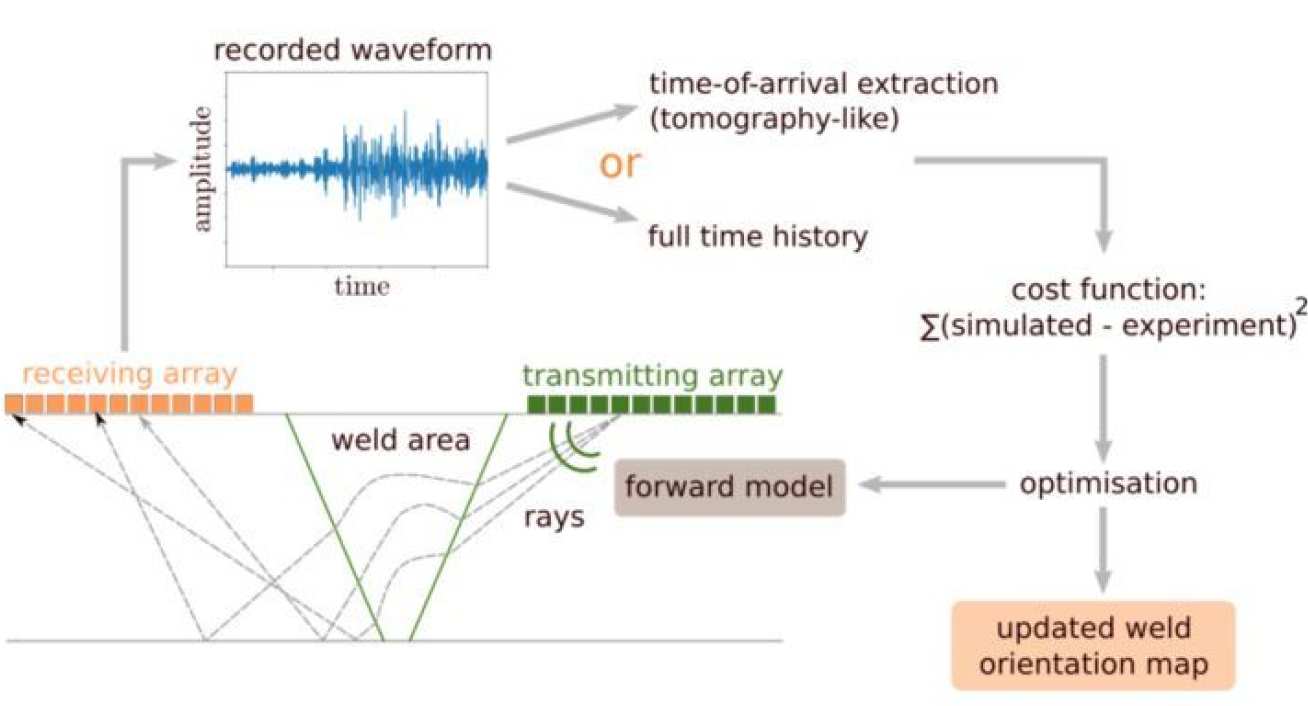

Corrosion resistant alloys (austenitic welds, castings, claddings) are commonly used in safety-critical components of nuclear power plants, but their inspection poses a significant challenge owing to their complex microstructure. Coarse grains are responsible for scattering the ultrasonic wave at each grain boundary, which results in a very high level of structural noise and attenuation of the wave. In the case of welds, the grains are columnar and preferentially aligned which deviates the ultrasonic beam from the straight path. All these effects make the inspection very difficult, if not impossible. The Imperial College NDE group is a part of a larger consortium tackling this challenge. Our specific area of work is to develop techniques for characterisation of the microstructure and to use this information in adaptive inspection/imaging algorithms. We combine phenomenological weld modelling with both finite element and ray simulations to determine methods allowing for the identification of the average local grain orientation. The ultrasonic characterisation is expected to help to break the barrier of applicability of ultrasonic inspection to complex materials. |