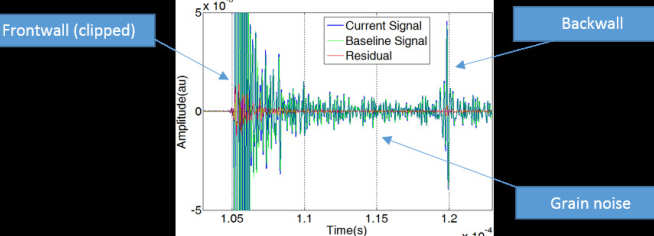

High temperatures (up to 700°C) will be used in the next generation of power stations to improve efficiency. In such high temperatures, large grained materials are more desirable due to their higher creep strength. However, the ultrasonic inspection of highly textured materials is made difficult by the presence of different principal orientations of grains/grain colonies. This leads to scattering of the incoming ultrasonic wave from grain/colony boundaries. The scattering increases the noise level and the attenuation decreases the amplitude of echoes from defects. Thus signal to noise ratio is often too poor for the test to be viable. However, as the grain noise is coherent, it is possible that if a structural health monitoring approach is used in which a baseline is subtracted from the current signal, then the grain noise will be removed. Typical signals collected from immersion tests and the residual after subtraction are shown in Fig 1, which shows that the grain noise is efficiently reduced by baseline subtraction.